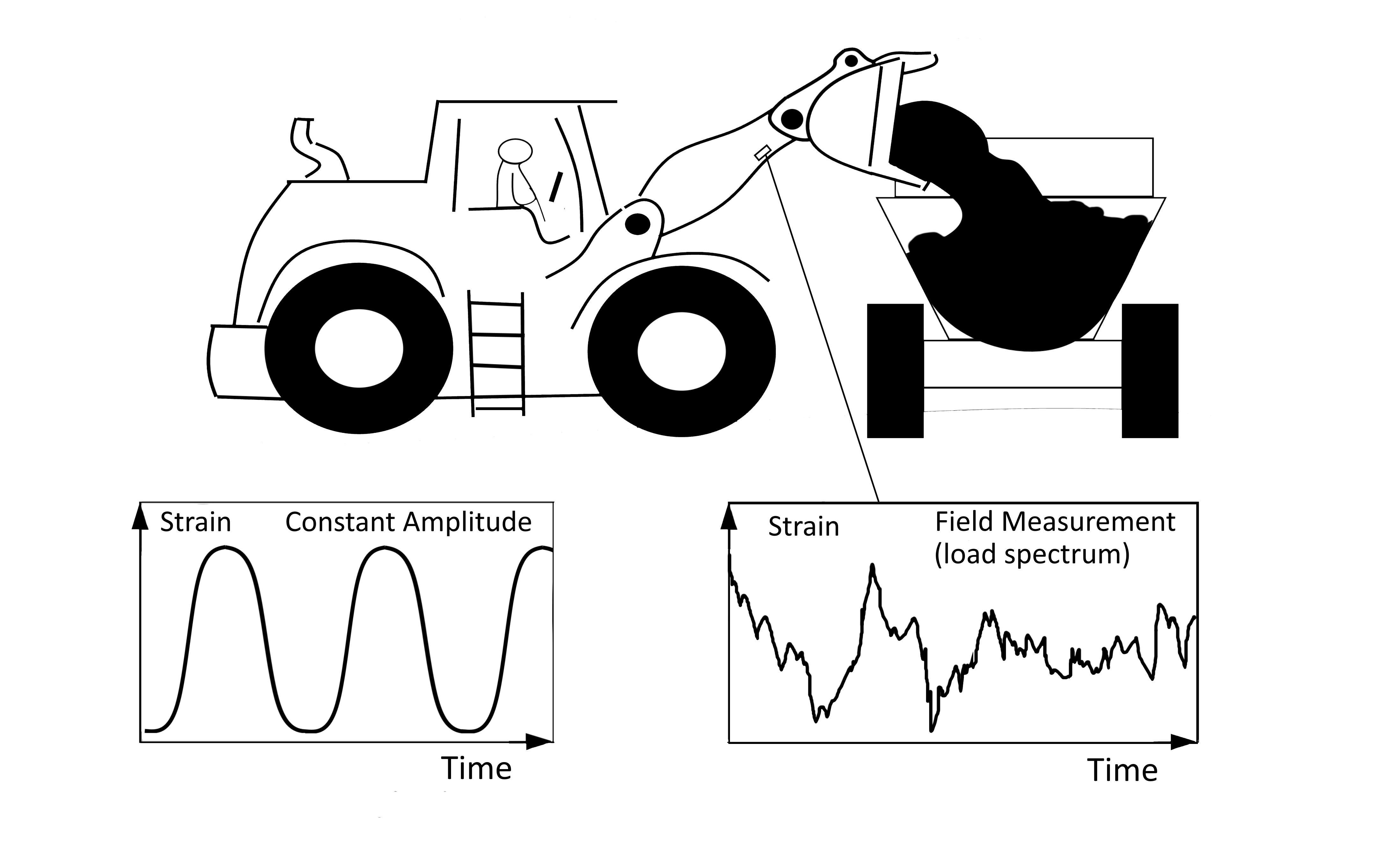

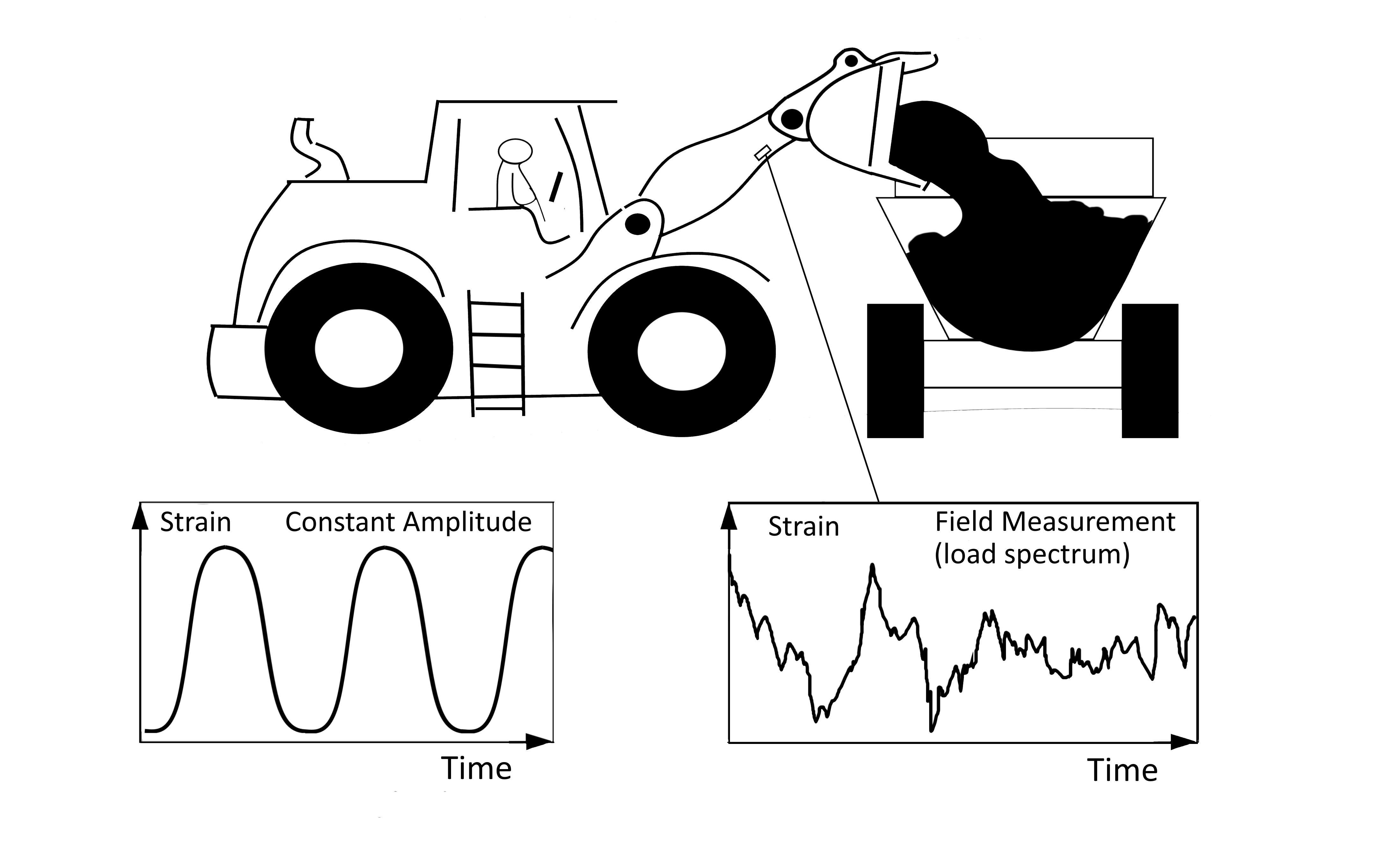

The fatigue load on most structures does not have a constant amplitude all the time. During the service life, the structure undergoes different size of the stress range during the various load cycles. In general, a longer service life is obtained when there are a lot of small stress range cycles and only a few of the maximum value. Thin load spectrum causes less damage than full load spectra (constant stress range all the time).

Picture 1: Load history

There are many ways to measure and evaluate the load spectra through filed measurements and different methods for counting the number of stress cycles and the stress range during each specific cycle.

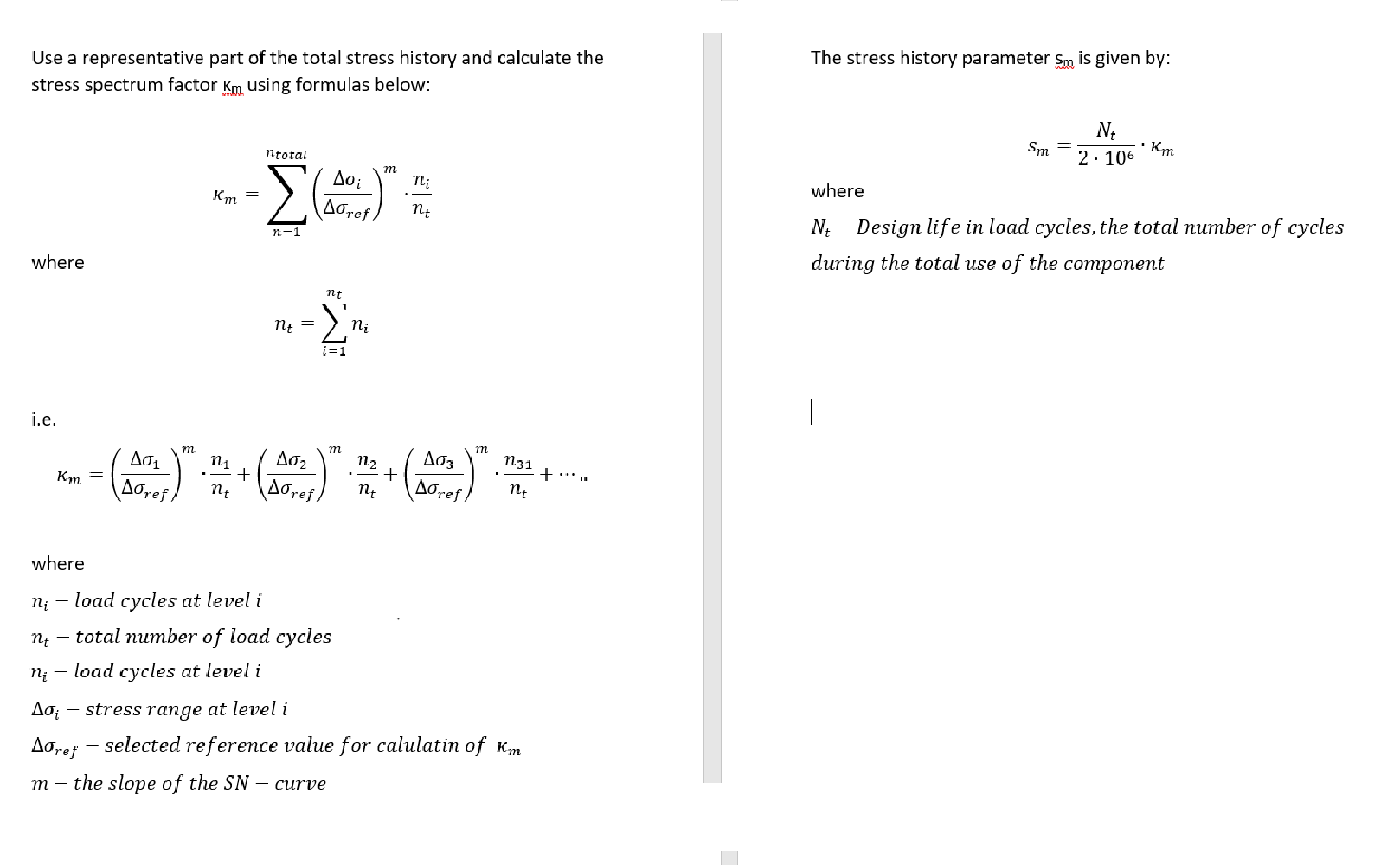

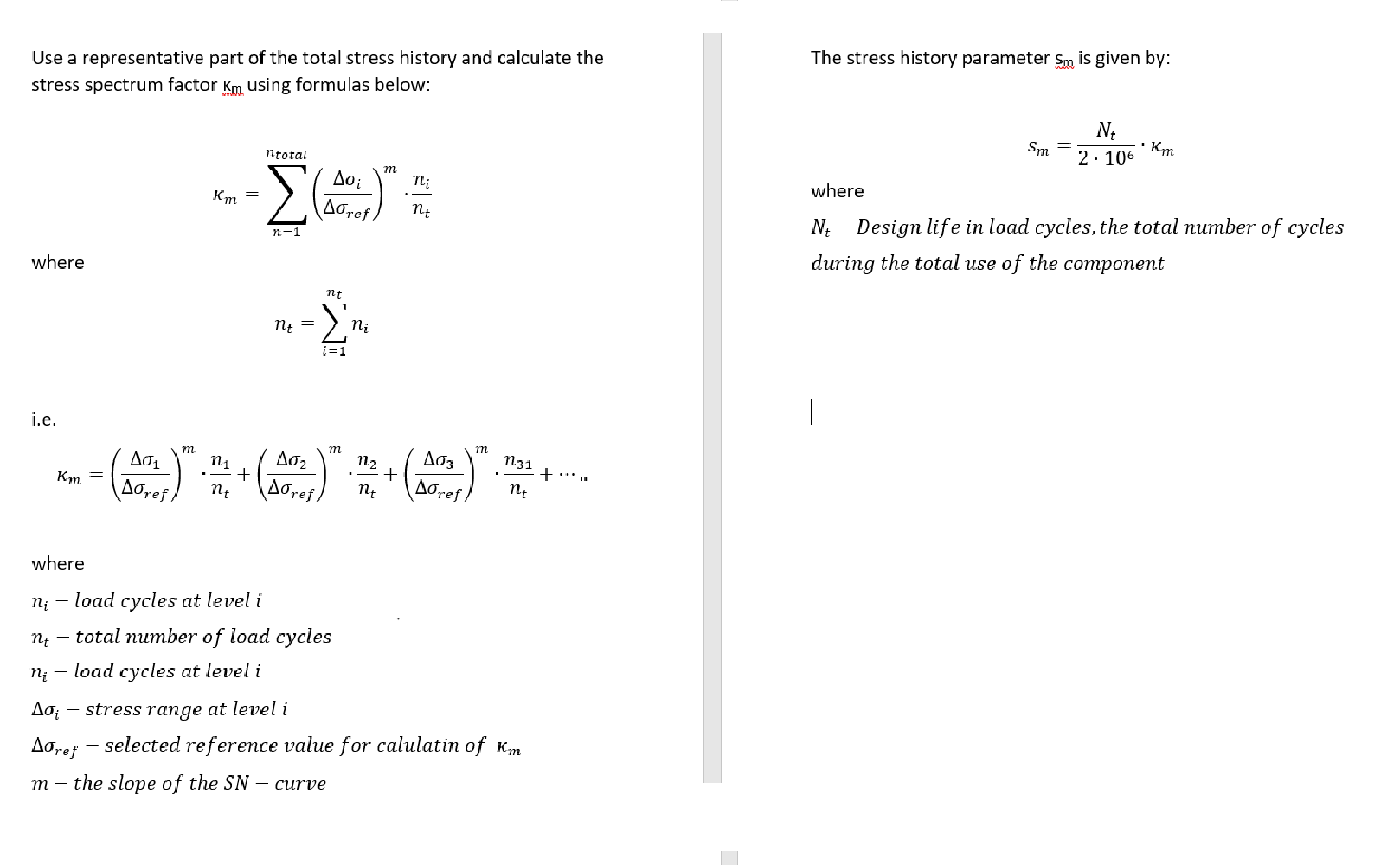

The stress history parameter is then used in the design computations leading to the design criteria.

One problem for the designer is often that the load spectrum is to some extent unknown. This can lead to the dangerous conclusion that the fatigue life is not possible to predict. Our recommendation is in these cases to use reference cases and try to estimate the relative life of e.g. a new design compared to an older one. Also, some guiding values can be found in literature and design guidelines.

Strain gate field measurements followed by evaluation of the measured data is the best tool to find the best value for the stress spectrum factor. Then it finally gives the stress history parameter used in the design criteria, picture 2.

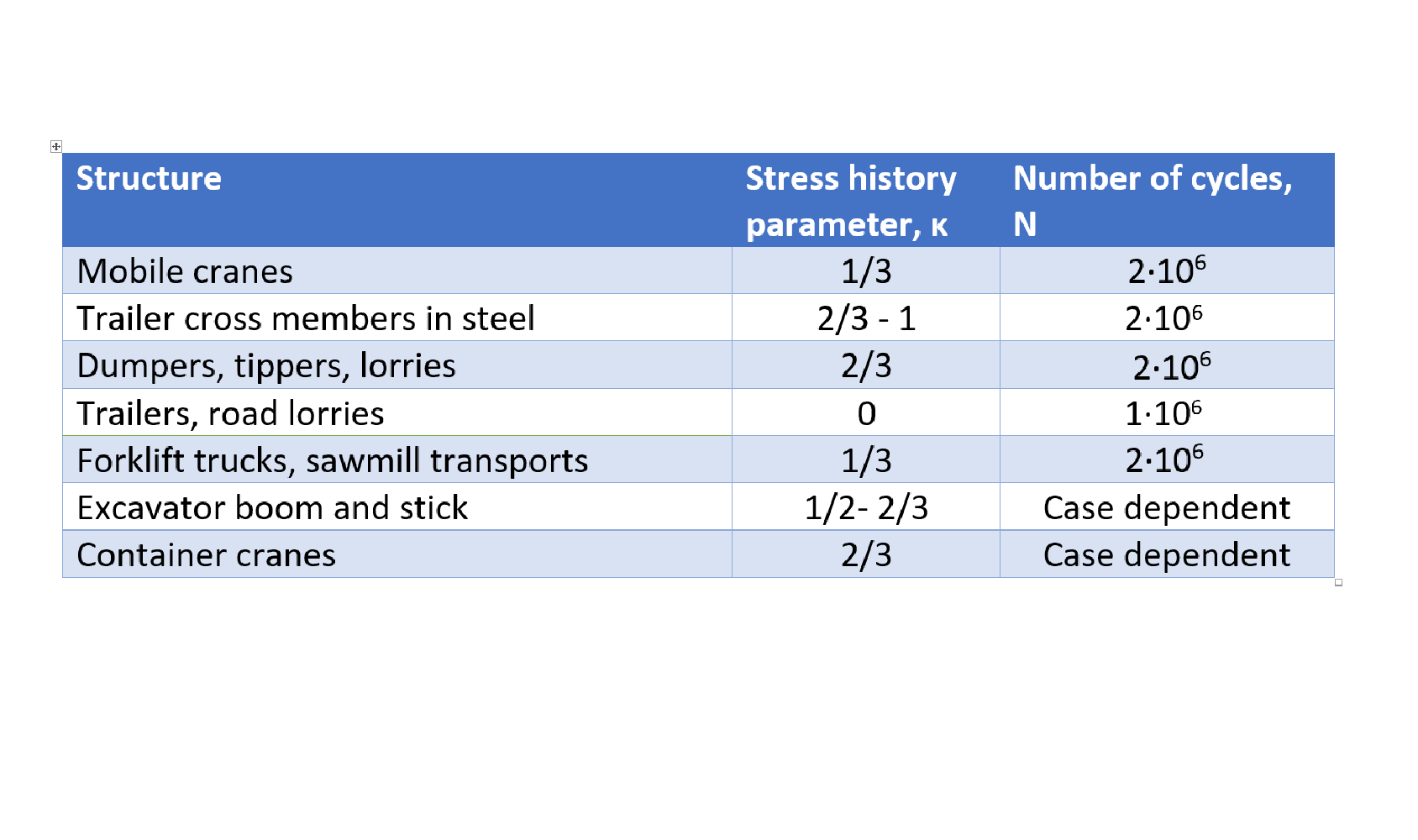

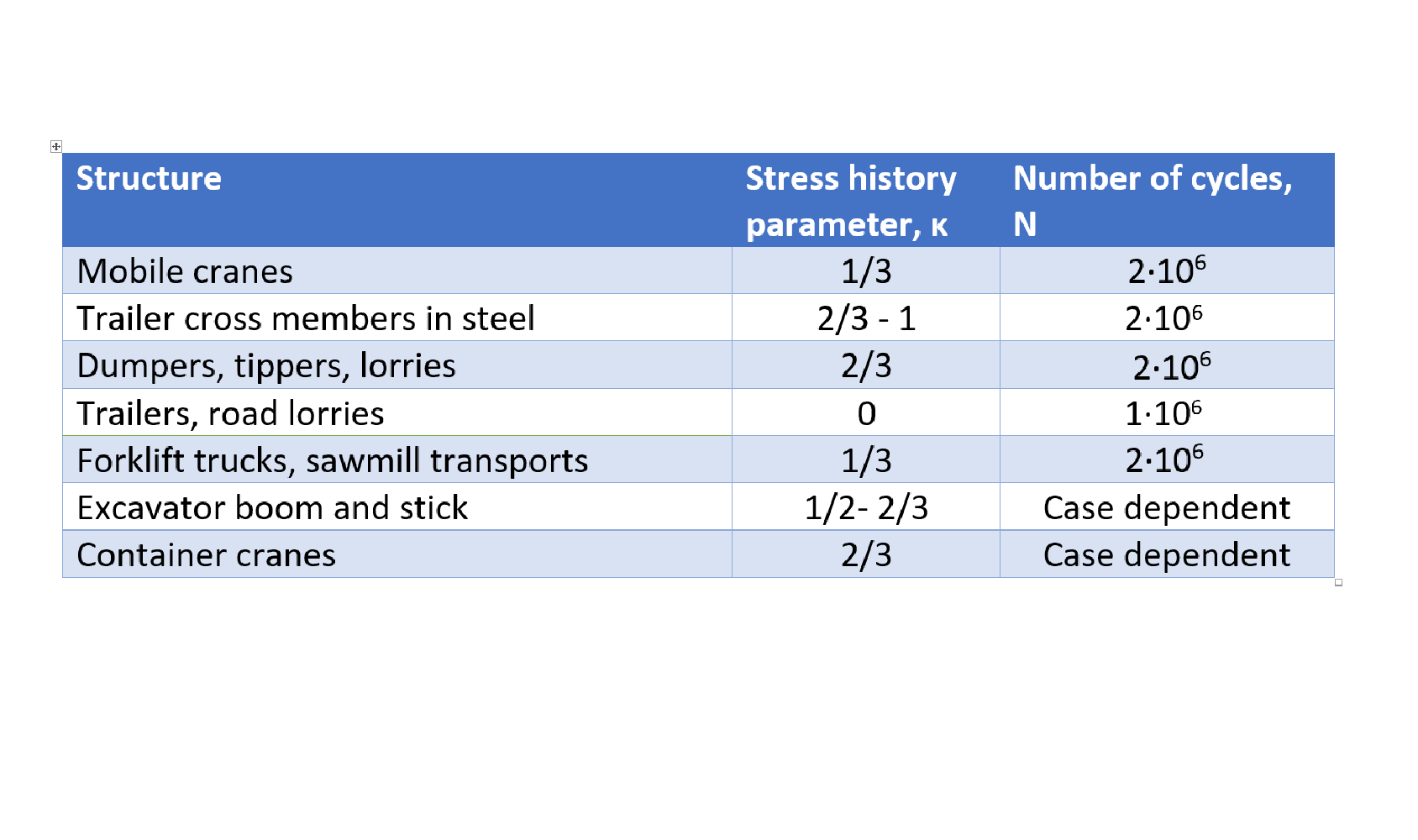

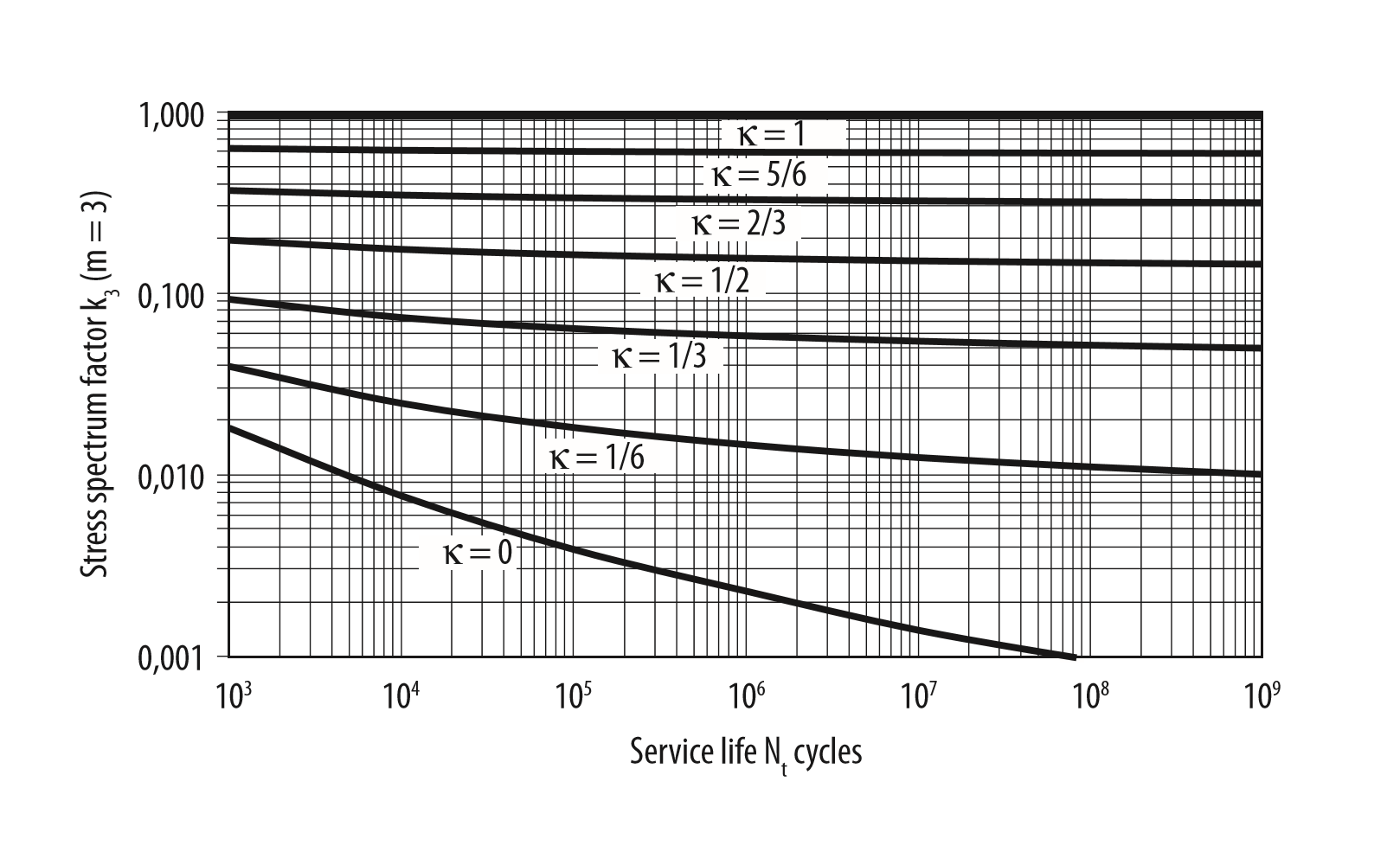

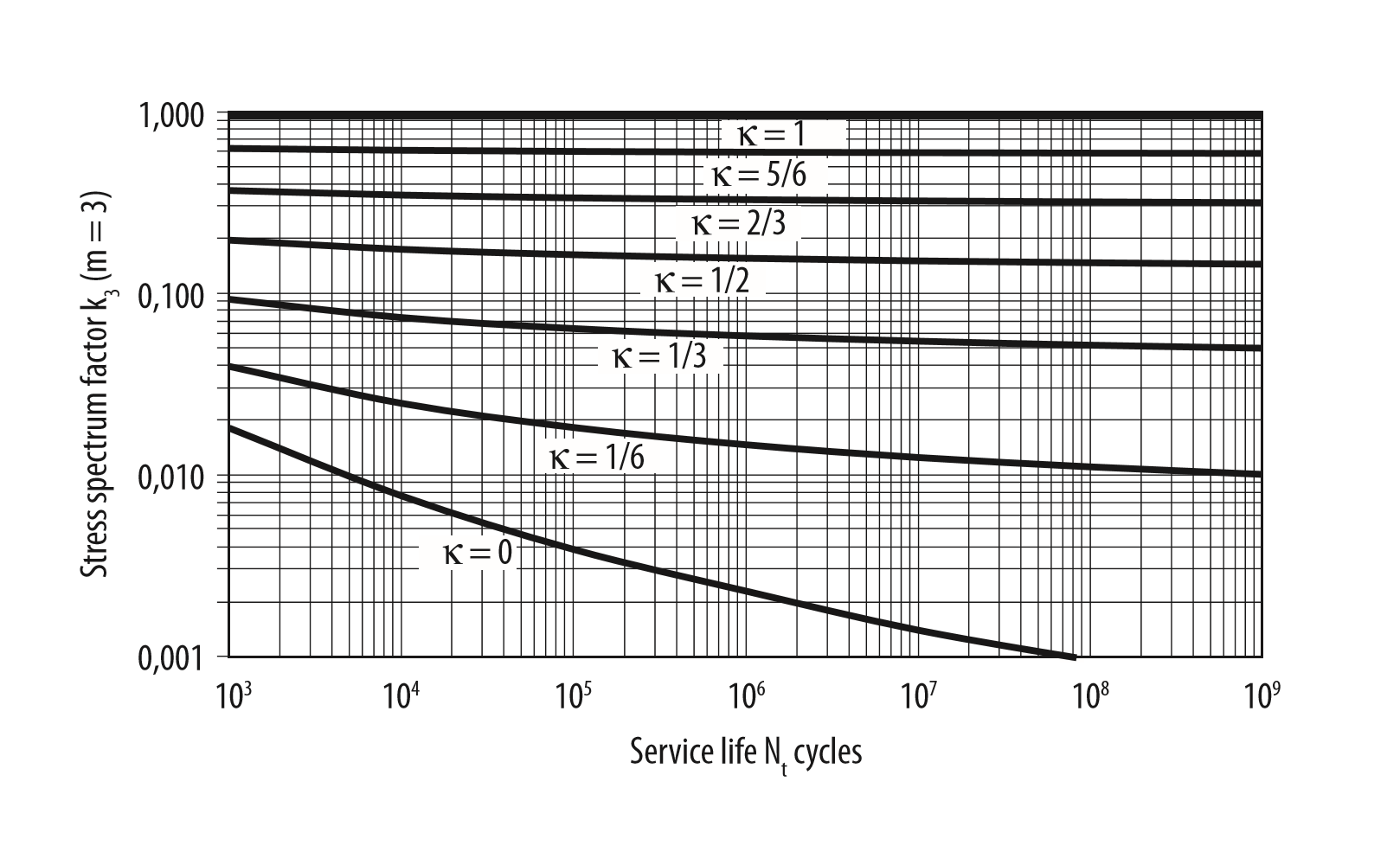

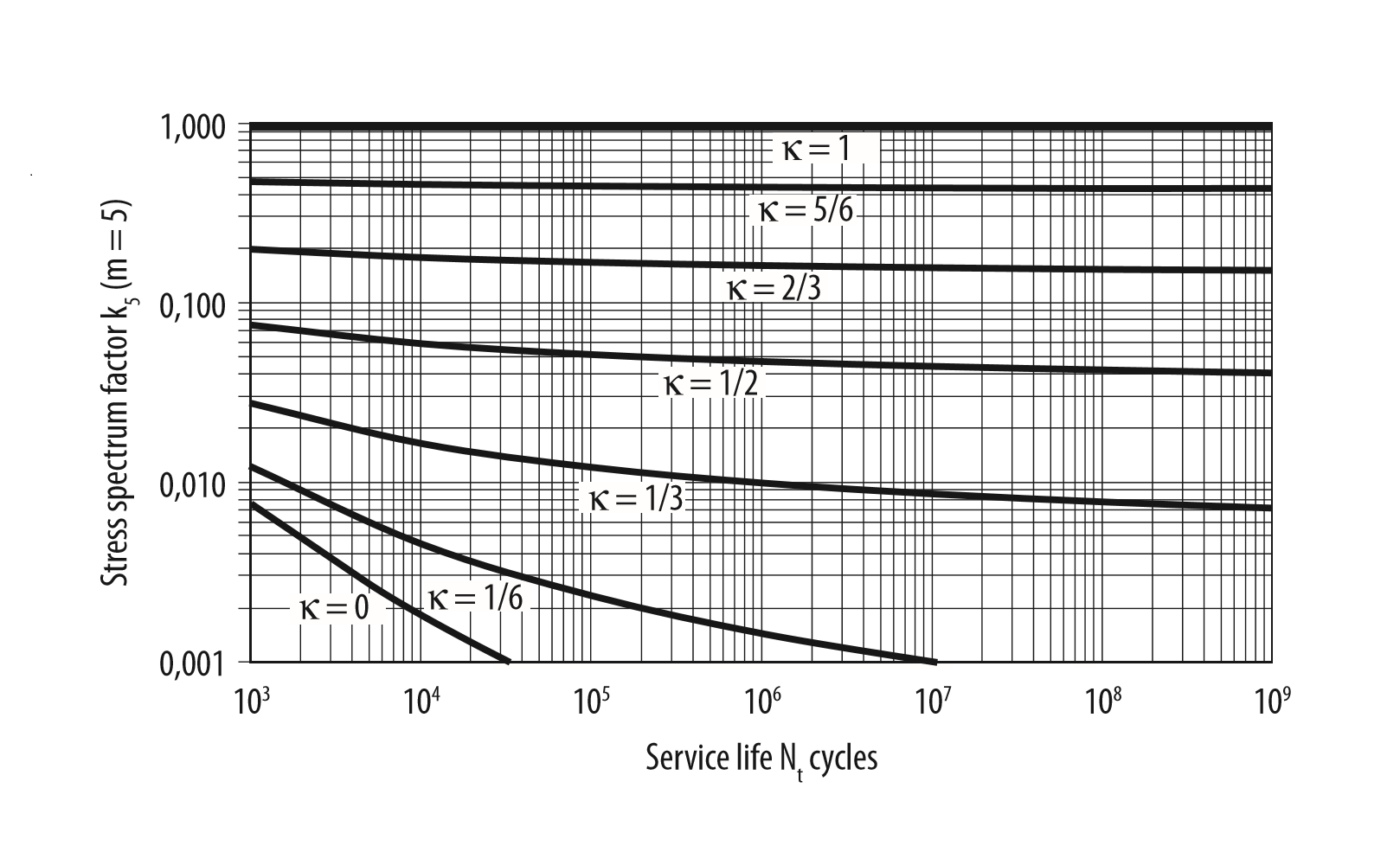

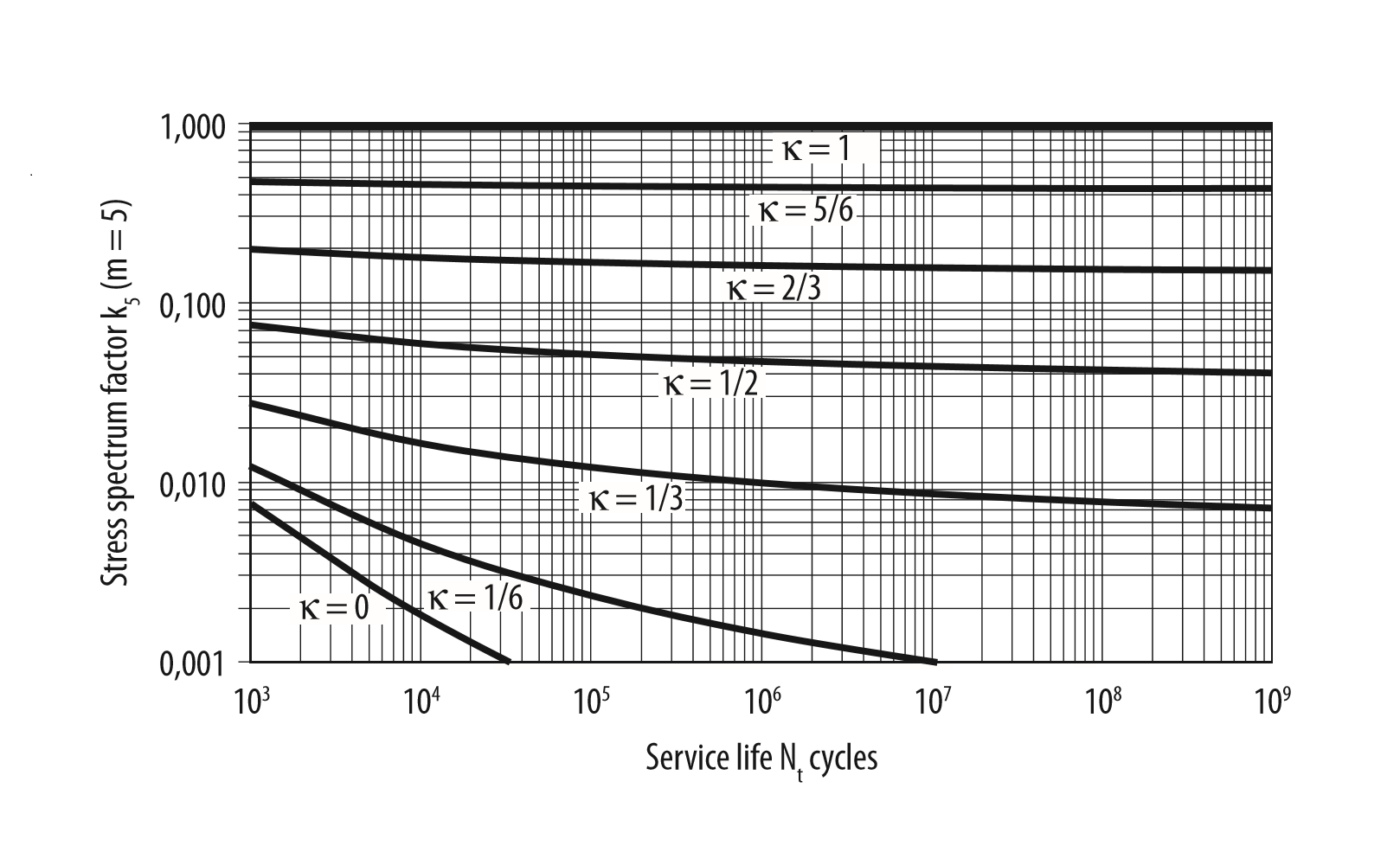

In some cases, typified stress histories can be used, when there is empirical knowledge about the specific structure. Estimate firstly the collective parameter, picture 3. Depending on the design case (the m-values) the stress spectrum factor can be found, picture 4 and 5.

Picture 2: Spectrum factor and stress history parameter calculation

Picture 3: Typified stress histories and corresponding stress history parameter.

Picture 4: Stress spectrum factor for m=3.

Picture 5: Stress spectrum factor for m=5.